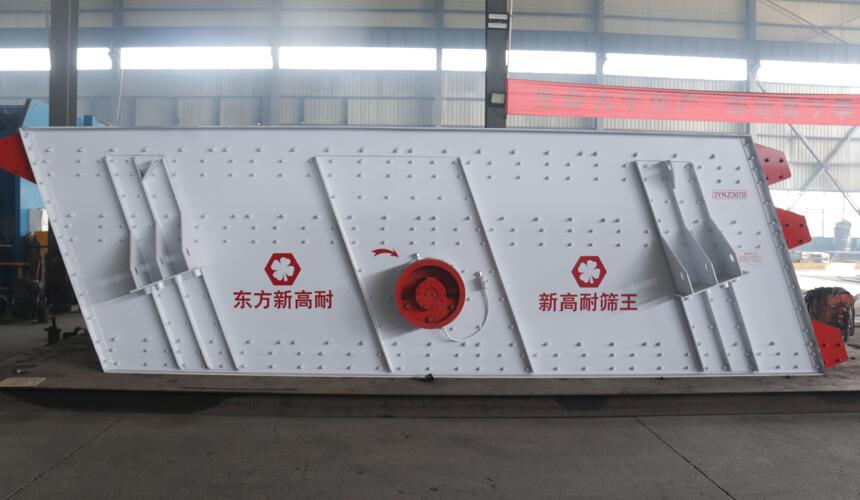

Applicable materials

YKQ series vibrating screen, commonly known as light screen, is suitable for screening limestone, granite, basalt, non-ferrous metal ores and other materials.

Scope of application

YKQ series vibrating screen is a type of circular vibrating screen and is widely used in screening processes in sand and gravel aggregates, metal mines, coal, chemical industry and other fields.

Internal Structure

It is mainly composed of vibration sources, sieve, vibration reduction device and base.

+8617761642222

+8617761642222